Building profits means you have business and manufacturing processes in place and people committed to following and improving the processes.

Jason does it again.

Jason, knew he wanted to make sure every job was profitable. As GM, Jason ran a job shop. He disliked inefficiencies in all areas of his shop. He wanted to get jobs going quickly. Jason had jobs quoted mostly from repeat business.

Next, Jason figured he could use software to save him time on the floor and in sales. So, he put software in place. He didn’t take the time to prepare.

Next thing Jason knew, he found himself enmeshed in late deliveries, high DMRs, work centers with long set up times, and upset customers. The shop produced small profits, even though the shop ran at capacity. Jason wondered if the jobs he had really fit his shop’s capabilities. The jobs often needed rework by engineering, were small runs, and pushed his team’s ability to deliver on time.

Jason failed to plan. He failed to define and communicate processes. The shop accepted just about all customers willing to pay. Jason had no system to identify and qualify customers. And Jason tried to automate processes that were not well defined.

It turns out you can’t automate a process that doesn’t exist.

Building profits job by job implies

There’s a plan

Manufacturers who plan, know the types of jobs they want to work with. They know how match the job well with the capabilities of the shop floor, the skills of the supervisors and capabilities of operators and work centers. They know their processes are well tuned to the types of jobs they accept.

How does this work in a high mix job shop?

Since there are even more “moving parts” in high mix environment, it is even more crucial that shops have a plan: well defined standards, well defined processes, well trained people, and supervisors and leaders who are committed to the company direction and values. If not it will fall to the managers to “save the day.”

Processes are in place to track costs.

Tracking costs of your materials, direct labor, overhead, OT, down time, marketing and sales, and the cost of order-to-delivery time can be challenging. Understanding the processes and using the right tools to streamline can make a huge difference.

Shops who achieve their goals, feed the marketing, sales, and quoting funnel with the right jobs and number of prospects to fit the shop’s capabilities.

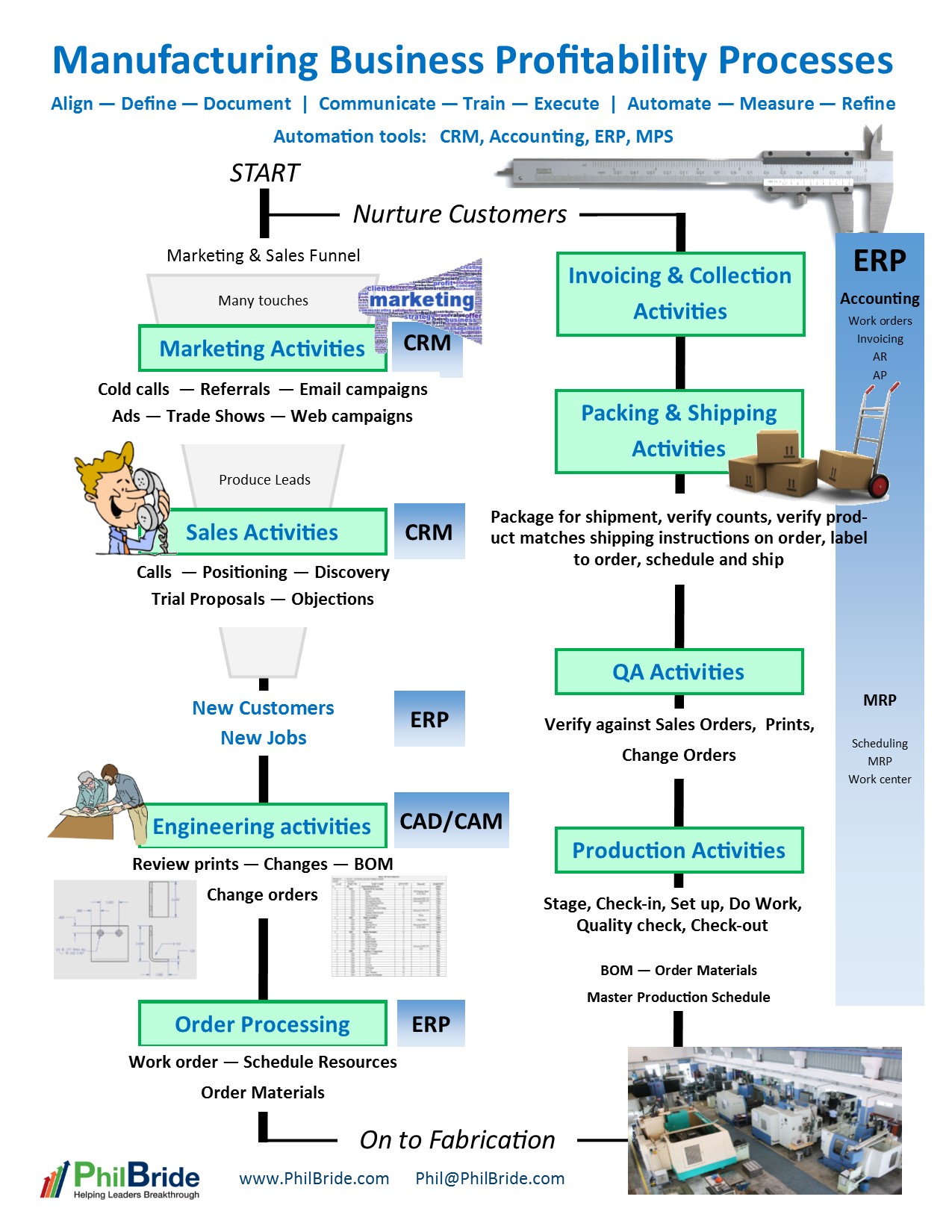

Driving efficiencies and profits start with defined standards (or KPIs) for all steps in processing a job. Key people can define standards for marketing, sales, order processing, engineering, down time, set up time, production time, quality assurance, packaging and shipping and delivery. Define standards and processes one at a time until you have a system that works.

Employees buy into the plan and the processes

Employees buy into the plan and the processes

Employees who buy into the plan, that is, who are engaged, know how to manage and improve the processes. Technicians and supervisors can spot inefficiencies and propose standards and processes to improve.

Improvement rests in well defined processes, written and articulated with well communicated standards. There is no such thing as over communication. Engaged supervisors and managers back up the communication effort.

The shop floor staff then can handle issues that invariably pop up. When employees buy into the plans and processes, they take pride in their work.

This results in staff offloading many issues. Management’s firefighting and saving-the-day activities reduces.

With engaged employees shops can systematically drive profits up per job.

Processes exist to automate

With a plan in place, employees that buy in, and processes defined, it’s time to automate. The more planning and processes put in place the less “fixing” and “saving the day” happens later.

Automating processes can save a ton a time. Shops can get a handle on costs and profitability through job cost reports, managing change orders, managing customer relationships better, allocating direct labor and overhead cost more accurately, managing processes to reduce DMRs and OTD, among others.

As the people, processes, and plans align to increase efficiencies, decrease costs, improve OTD and quality, profits will follow. Short term fixes and shortcuts mean just that—short term.

So, now what…

Building profits in each job takes initiative by the key people in the company.

- It takes an engaged team and execution of the key business processes affecting success.

- And it starts with management planning for success.

To wrap up, check out this complimentary InfoGraphic guide to business processes affecting building profits in each job.

Contact Phil today at 503-753-9971 or email at phil@PhilBride.com for a complimentary 30 minutes to talk about your situation.

Get unstuck. Make things happen.